Cepheo Foundation

Our custom modules

HowTo

License overview

Batch jobs

Business events

Foundation release highlights

Foundation history

Base.2022.2.2.10

Base.2022.2.2.11

Base.2022.8.2.15

Base.2022.8.2.16

Base.2022.8.2.19

Base.2022.11.2.21

Base.2024.10.2.65

Base.2025.2.3.2

Base.2025.2.3.4

Base.2025.2.3.5

Base.2025.3.3.6

Base.2025.11.3.14

Base.2026.1.3.15

Release notes Foundation

What is Cepheo Foundation

Cepheo Business Documents

Business Document examples

Business Documents configuration

General for all documents

Sales order configuration

Sales invoice

Sales packing slip

Purchase order

Project invoice

Quotation

Interest note

Work report

Dynamic payment information

Release highlights Business Documents

Release notes Cepheo Business Documents

Cepheo Currency Import

Exchange rate provider

Triangulation

Release highlights Currency Import

Release notes Currency Import

What is Cepheo Currency import

Cepheo Engineering

Engineering setup

Engineering parameters

Engineering global parameteres

Change notification parameters

Classification Codes Setup

Item property setup

Manufacturer Setup

Material Quality Setup

Product setup

Spare Parts Setup

Released Item Setup

How to use Engineering

Release highlights Engineering

Engineering history

Rev.2022.5.2.5

Eng.2022.5.2.11

Eng.2022.5.2.12

Eng.2022.9.2.13

Eng.2022.11.2.14

Eng.2022.12.2.16

Eng.2023.1.2.17

Eng.2023.1.2.18

Release notes Cepheo Engineering

What is Engineering

Cepheo Estimator Metrics

Estimator metrics configuration

Estimator metrics analyze

Release highlights Estimator metrics

Release notes Estimator metrics

Cepheo Expense

Cepheo Expense Power App

Cepheo Human Resources

Setup HR extension

Use HR extension

Release highlights HR extension

Release notes HR extension

What is Human Resources Extension

Cepheo Installation

How to use Installation

Setup Installation

Release highlights Installation

Release notes Installation

Cepheo Ledger Import

Cepheo Payment Certificate for Construction

Release highlights Payment certificate for construction

Release notes Payment Certificate for Construction

Cepheo Payroll Integration

Setup of payroll

How to use payroll

Release highlights payroll integration

Release notes Payroll Integration

What is Cepheo Payroll

Cepheo Price import

Cepheo Project Control

Risk setup and use

Subscription setup and use

Project invoice proposal

Release highlights Project extension

Release notes Project control extension

What is Cepheo project control

Cepheo Project Cost Allocation

Release highlights Project Cost Allocation

Release notes Project cost allocation

What is Cepheo Project Cost Allocation

Cepheo Project Management

Release highlights Project management

Release notes Project management extension

What is Cepheo Project Management

Cepheo Sales Integration

Use sales integration

Setup sales integration

Release highlights Sales integration

Relase notes Sales Integration

Cepheo Service Integration

Use service integration

Setup service integration

Service integration parameters

Work order lifecycle models

Maintenance workers

Cepheo power platform solution

Setup Cepheo Asset management app in Resco

Virtual entities

Release notes Service Integration

Cepheo Shipment Booking

How to use Shipment booking

Notification contacts

Consolidate shipment bookings from Create Shipment booking dialog

Maintain content lines on a Container on a Shipment booking

Shipment booking setup

Shipment booking external values

Convert addresses and recipients to address quick ID's

Convert label

Convert Carrier, Carrier services and/or Additional service

Convert country, state and county

Convert currency code

Convert print favorite

Convert shipment payer account

Convert (WHS) Container types

Convert shipment booking status

Convert security group

Shipment booking parameters

Document transformations

Shipment booking senders

Shipment booking labels

Shipment booking print favorites

Shipment booking security group (nShift Delivery)

Carrier container types

Shipment booking cost rule

Printers and Printer locations

Import Carrier

Shipment booking app setup

Release highlights Shipment booking

Release notes Shipment Booking

What is Shipment booking

Cepheo Subscription

Setup of subscription

How to use subscription

Release highlights Subscription

Release notes Subscription

Cepheo Test and Certification

Certification and testing

Release highlights Test and certification

Release notes Test and Certification

Cepheo Timesheet

Timesheets

Hour balance

Timesheet extension release highlights

Timesheet extension history

Ts.2022.3.2.15

Ts.2022.3.2.16

Ts.2022.4.2.17

Ts.2022.4.2.18

Ts.2022.4.2.19

Ts.2022.5.2.22

Ts.2022.9.2.24

Ts.2023.2.2.30

Ts.2023.2.2.31

Ts.2023.4.2.33

Ts.2025.3.4.9

Ts.2025.04.4.14

Release notes Timesheet extension

What is Cepheo Timesheet

Cepheo Vendor Catalog

Cepheo Quality and Sample Management

What's new or changed in Quality and Sample Management

Version history

Release notes Cepheo Quality and Sample Management

Version 2025.11.1.9

Version 10.42.66.2

Version 10.42.66.3

Cepheo Quality Sample Management Version 2025.12.1.40

Introduction to Quality and Sample Management

Advanced Quality Control

Setup

Advanced Quality Control

Fail immediately

Update Advance Quality Order Phase based on Quality Order Status

Register test results

Advanced quality work when merging batches (reference type = Inventory)

How to transfer Out of Spec test results to batch attributes

Reservation concept for Batch and warehouse enabled products

View test results

Sample management

Batch disposition master

Disposition code not allowed for location

Preparing disposal of archived samples

Frequencies

Advanced quality associations with ref type different from ‘Quality sample’

Stability testing

Printing of sample labels

Advanced quality associations with reference type ‘Quality sample’

View item tracing

Printing of quality order report

How to transfer test results from bulk batch to Finished Goods batch

Item sampling

Transfer disposition code from Bulk product to finished goods

Manual transfer of test results to batch attributes

Automatic creation of Non-conformance orders

How to enable automatic transfer of test results to batch attributes

Quantities field on Advanced Quality orders

Warehouse management application

Overview - WMS app

Set up a mobile device menu items for receiving processes

Set up a mobile device menu item for changing batch information

Set up a mobile device menu item for registering or adding test results

Set up a mobile device menu item for setting a sample status

Set up a mobile device menu item for changing license plate disposition code

Set up a mobile device menu item for moving sample type

Set up a mobile device menu item for creating a sample

Configure detours for steps in mobile device

Automatic release of license plates

Quality Work Forecasting

Batch Manufacturing Date

Update of manufacturing date

Setup of tracking number group

Update of Expiration Date

Batch Manufacturing Date

Formula Yield Extension

Electronic signature

Quality workspace

Quality workspace

Tab page Advanced quality orders/test results

Tab page Quality samples

Tab page Summary

Data entities

Security

Extension points

Cepheo Global Data Management

Installation

Global data management setup

Validate

Example

Refresh fields setup

Create a data table from a data entity

Recreate company updates

Relation

Table browser

Table setup

InventItemGroupItem

Default values

InventModelGroupItem

Fields setup

Push records

Selection management

Company Distribution

Global data management setup

Record updates

Periodic

Batch push data

Batch push data - multi-threaded

Clean up Event log

Relating existing records

Clean up Record updates

Active is set to Yes

Periodic

Update triggers

Refresh fields setup

GDM monitoring

Overview per company

Managing data

GDM Security setup

Cepheo GDM setup

The company groups setup

Global data management owner

Setting the Cepheo GDM Parameters

Cepheo GDM setup

Known issues

Example: Create new customer

Release highlights Cepheo Global Data Management

Cepheo Global Data Management version 2025.12.1.38

Cepheo Global Data Management version 10.42.66.1

Cepheo Global Data Management version 2025.11.1.7

What is Cepheo Global Data Management

Release notes Cepheo Global Data Management

Cepheo Shipping Packaging Management

License configuration key

License

Terms and abbreviations

Security

Release highlights Cepheo Shipping Packaging Management

Cepheo Shipping Packaging Management version 2025.11.1.3

Cepheo Shipping Packaging Management version 2025.12.1.4

Shipping Packaging framework

Packaging item groups

Packaging management on sales return orders (RMA)

Packaging management automated as part of the sales/purchase order packing slip update

Reporting packaging without order reference

Packaging management on loads/shipments

Packaging management as part of transfer journals

Shipping packaging management setup

Reporting packaging transactions to a pool owner

Settle packaging

Packaging management as part of transfer orders

Packaging management manually on a sales/purchase order

Packaging on-hand

Setup of Packaging Pools

Packaging management for Intercompany and direct delivery

Using mobile device for registration of packaging

Packaging management on a sales/purchase order

Shipping Packaging framework

Advanced packaging management for products

Packaging management for carriers

Packaging groups

Packaging types

Packaging filters and overview

Packaging management for products

Linking registrations to shipment/loads

Packaging management for custoners/vendors

Suggestion production process

Packaging management for transfer orders

Data Management - Entities

Release notes Cepheo Shipping Packaging Management

Feature Management for Cepheo Shipping Packaging Management

What is Cepheo Shipping Packaging Management

Cepheo Product Documentation Management

Security

Document overview groups

Data entities

License configuration key

Product data sheets and batch certificates

Data sheets (PIM\Common\Data sheet)

Basic setup

Printing certificates for a batch

Additional information on data sheets and certificates

Electronic signature – Approve data sheet

Document-specific information

Product data sheets and batch certificates

License

Terms and abbreviations

Release notes Cepheo Product Documentation Management

What is Cepheo Product Documentation Management

Cepheo Product Data Management Extension

Security

BOM Comparison (PIM\Common\Released products)

License configuration key

Terms and abbreviations

Data entities

Customer-specific order settings (PIM\Common\Released products)

Product lifecycles

License

What is Cepheo Product Data Management Extension

Release notes Cepheo Product Data Management Extension

Cepheo Extended Production Handling

License key

Terms and abbreviations

Release highlights Cepheo Extended Production Handling

Cepheo Extended Production Handling version 2025.12.1.4

Cepheo Extended Production Handling version 2025.11.1.3

Data entities

Automatic reporting as finished for sub-productions

Prerequisites and setup

Reporting quantity as finished from finished product

Mix pools

Automatic reporting as finished for sub-productions

Ending productions from finished product production

Concept

Reporting negative quantity as finished from finished product (roll-back)

Reporting overproduced quantity as finished from finished product

Supported process flow

License configuration key

Security

Consolidated batchorders

Consolidated batchorders

Choosing planned bulk orders only

Choosing planned pack and bulk orders

Choosing planned pack orders only

Menus for the planner

Working with the "Firm consolidate batch orders" form

Working with the "Consolidated batch order" form

Quantity view for consolidated batch order

What is Cepheo Extended Production Handling

Release notes Cepheo Extended Production Handling

Cepheo Information Display for Batch Products

License

License configuration key

Entities

Security

Batch Information Display

Batch information display for on-hand

Batch information display groups

Batch information display setup

Batch information display for reservation

Batch Information Display

Batch information display on ‘Batches’ form

Item batch information display group

On-hand list and display dialog

Batch information display for sales order add lines-function

Batch information display for Batch merge

Release notes Cepheo Information Display for Batch Products

What is Cepheo Information Display for Batch Products

Cepheo Advanced Customer Approval

Security

ACA and Intercompany

ACA for trade agreements (Prices)

ACA for sales quotations

Terms and abbreviations

License configuration key

Data entities

Customer exclusion

ACA for sales agreements

Advanced Customer Approval (ACA)

ACA Inquiry forms

Printing sales order

Setup for Advanced Customer Approval

Show only approved products

Using ACA information for purchase

Advanced Customer Approval (ACA)

What is Cepheo Advanced Customer Approval

Release notes Cepheo Advanced Customer Approval

Cepheo Advanced Vendor Management

License

Advanced Vendor Approval (AVA)

Purchase order

Purchase agreement

AVA for trade agreements (Prices)

Advanced Vendor Approval (AVA)

Setup of AVA's on a released product

Source and destination control

License configuration key

Security

Vendor exclusion

Data entities

Vendor Audit Management

Audit records

Vendor Audit Management

Number sequence for Vendor Audit

Vendor audit score

Vendor audit status

Audit requirement

Vendor and manufacturer certifications

Terms and abbreviations

Release notes Cepheo Advanced Vendor Management

What is Cepheo Advanced Vendor Management

Release notes AVM

Cepheo Label Extension for Warehouse Management

Label viewer tool

Warehouse document routing layout

Security

Terms and abbreviations

License

Entity

Configuration keys

What is Cepheo Label Extension for Warehouse Management

Release notes Cepheo Label Extension for Warehouse Management

Release notes LEWM

AX2012

Cepheo MVA-melding

MVA Setup

MVA Reporting

Step 4: Reporting

Step 4 | Section 1: Tax reports

Step 4 | Section 2: Standard tax codes

Step 4 | Section 3: Tax specifications

Step 4 | Section 4: Report remark

MVA Multicompany setup

MVA Intercompany setup

MVA Intercompany Tax report

Cepheo SAF-T reporting

Item sampling

Updated

by Peter Kure Bek-Thorngreen

Item sampling

Path: (Quality\Setup\Quality control) Item sampling is a crucial component of quality management systems, used to determine the quantity of an item that needs to be tested during quality inspections. This process plays a pivotal role in quality orders, ensuring that the right amount of inventory is subjected to testing.

Item sampling in the Advanced Quality and Sample Management module is different from the standard quality module, although the same interface is used as a base.

Here are some of the major differences.

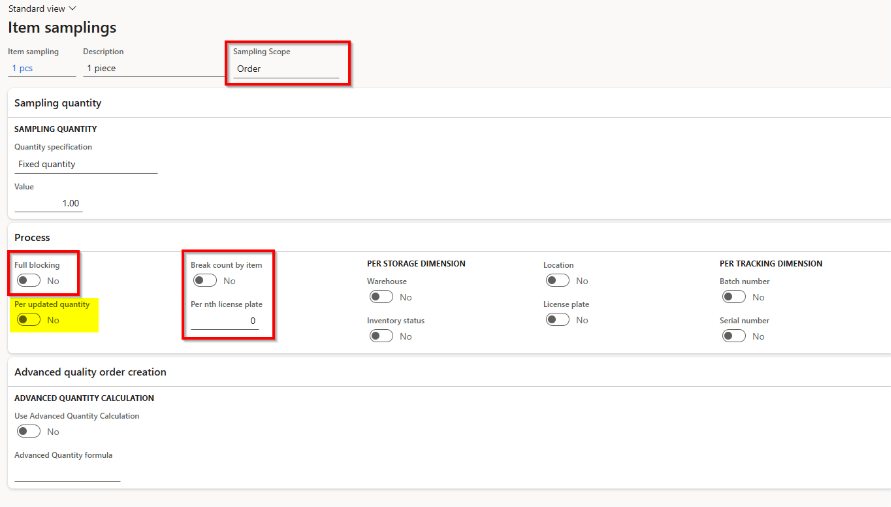

In the screenshot below the areas marked with a red box are not used by the Advanced Quality and Sample Management module.

But the “per updated quantity” field marked with yellow plays an important role in creating samples, calculating the right quantity for the Advanced quality order tests and other things. See below.

Key Features:

- No Inventory Transactions for Sampled Quantities:

- Advanced quality orders do not create inventory transactions for the quantities calculated by item sampling. This means standard inventory dimensions, like Inventory status, are not utilized, and restrictions have been removed for creating advanced quality orders.

- Destructive Testing Limitations:

- Destructive testing is not possible for quantities calculated by item sampling in advanced quality orders, due to the absence of inventory transactions.

- No Inventory Blocking:

- These orders are not used to perform inventory blocking – although it is possible. Instead, blocking is managed using disposition codes at batch or license plate (LP) levels.

- Storage and tracking dimensions

- In standard quality this controls how the system should find and treat items when a quality order is completed. If for instance a quality order fails, the system needs to block all items connected to this quality order. Using these dimensions the system can narrow down and only block the license plates received, but to do so the license plate dimension needs to be enabled.

- In Advanced quality and sample management the dimensions are used to add information to the sample. For the system to identify a license plate registered towards a batch it is needed to toggle the license plate and batch dimensions to yes.

Without this the system does not register a sample towards a license plate, which affects the quality work if the test group is set to license plate sequence.

- No On-Hand Inventory Requirement:

- There is no need for on-hand inventory availability at the dimensions of the quality order. This allows for testing samples of a batch before the main batch is received or moved during testing.

- Multiple Orders:

- Multiple open advanced quality orders can exist simultaneously for the same batch or sequence of license plates.

- Item Sampling Setup:

- The system can calculate the sample quantity as a sum of individual sample types, useful when a large sample is divided for various analyses. Attention to unit conversion rounding is advised to ensure accurate sample quantities. See sample types below

"Per Updated Quantity":

The "Per Updated Quantity" field is used to indicate if sampling should occur in response to the reception of goods, which is particularly relevant when receiving items in multiple shipments or batches over time.

When set to "yes," this field ensures that sampling is conducted based on the quantity received during each update or reception. This is useful in scenarios where items are received incrementally rather than in a single shipment.

Usage in Quality and Sample Management (QSM) Module:

In the context of the QSM module, this setting helps register the amount from which the sample should be drawn accurately. It is essential for calculating the correct sample quantity when dealing with advanced quality associations that reference types other than "Quality sample."

If "Per Updated Quantity" is not set, the system may face difficulties in determining the correct sample amount, potentially leading to discrepancies in sampling and testing procedures.

Restrictions:

For advanced quality associations with a reference type "Quality sample," this field should not be set to "yes." Doing so can disrupt the code responsible for creating advanced quality orders, resulting in incorrect numbers of orders or frequencies.

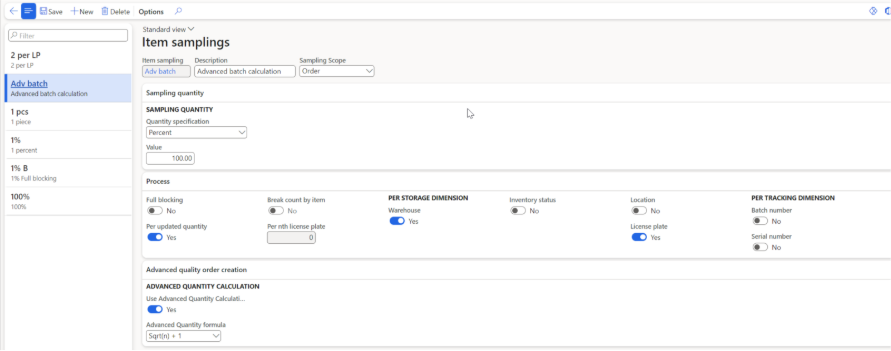

Advanced Quantity Calculation:

‘Advanced quantity calculation’ – Here you can select to sample sqrt(n)+1. This is a sample quantity that has been used in the industry for many years and is generally accepted by the FDA. The setup will only be available for the quantity specification of ‘Percent’. Example: Order qty is 1000 ea. 100 ea. are registered on an LP (item sampling 100% + calculated) an Adv. quality order is created for 11 ea. (√100= 10 + 1 = 11 ea.).

Figure 17: Item sampling setup