Cepheo Foundation

Our custom modules

HowTo

License overview

Batch jobs

Business events

Foundation release highlights

Foundation history

Base.2022.2.2.10

Base.2022.2.2.11

Base.2022.8.2.15

Base.2022.8.2.16

Base.2022.8.2.19

Base.2022.11.2.21

Base.2024.10.2.65

Base.2025.2.3.2

Base.2025.2.3.4

Base.2025.2.3.5

Base.2025.3.3.6

Base.2025.11.3.14

Base.2026.1.3.15

Release notes Foundation

What is Cepheo Foundation

Cepheo Business Documents

Business Document examples

Business Documents configuration

General for all documents

Sales order configuration

Sales invoice

Sales packing slip

Purchase order

Project invoice

Quotation

Interest note

Work report

Dynamic payment information

Release highlights Business Documents

Release notes Cepheo Business Documents

Cepheo Currency Import

Exchange rate provider

Triangulation

Release highlights Currency Import

Release notes Currency Import

What is Cepheo Currency import

Cepheo Engineering

Engineering setup

Engineering parameters

Engineering global parameteres

Change notification parameters

Classification Codes Setup

Item property setup

Manufacturer Setup

Material Quality Setup

Product setup

Spare Parts Setup

Released Item Setup

How to use Engineering

Release highlights Engineering

Engineering history

Rev.2022.5.2.5

Eng.2022.5.2.11

Eng.2022.5.2.12

Eng.2022.9.2.13

Eng.2022.11.2.14

Eng.2022.12.2.16

Eng.2023.1.2.17

Eng.2023.1.2.18

Release notes Cepheo Engineering

What is Engineering

Cepheo Estimator Metrics

Estimator metrics configuration

Estimator metrics analyze

Release highlights Estimator metrics

Release notes Estimator metrics

Cepheo Expense

Cepheo Expense Power App

Cepheo Human Resources

Setup HR extension

Use HR extension

Release highlights HR extension

Release notes HR extension

What is Human Resources Extension

Cepheo Installation

How to use Installation

Setup Installation

Release highlights Installation

Release notes Installation

Cepheo Ledger Import

Cepheo Payment Certificate for Construction

Release highlights Payment certificate for construction

Release notes Payment Certificate for Construction

Cepheo Payroll Integration

Setup of payroll

How to use payroll

Release highlights payroll integration

Release notes Payroll Integration

What is Cepheo Payroll

Cepheo Price import

Cepheo Project Control

Risk setup and use

Subscription setup and use

Project invoice proposal

Release highlights Project extension

Release notes Project control extension

What is Cepheo project control

Cepheo Project Cost Allocation

Release highlights Project Cost Allocation

Release notes Project cost allocation

What is Cepheo Project Cost Allocation

Cepheo Project Management

Release highlights Project management

Release notes Project management extension

What is Cepheo Project Management

Cepheo Sales Integration

Use sales integration

Setup sales integration

Release highlights Sales integration

Relase notes Sales Integration

Cepheo Service Integration

Use service integration

Setup service integration

Service integration parameters

Work order lifecycle models

Maintenance workers

Cepheo power platform solution

Setup Cepheo Asset management app in Resco

Virtual entities

Release notes Service Integration

Cepheo Shipment Booking

How to use Shipment booking

Notification contacts

Consolidate shipment bookings from Create Shipment booking dialog

Maintain content lines on a Container on a Shipment booking

Shipment booking setup

Shipment booking external values

Convert addresses and recipients to address quick ID's

Convert label

Convert Carrier, Carrier services and/or Additional service

Convert country, state and county

Convert currency code

Convert print favorite

Convert shipment payer account

Convert (WHS) Container types

Convert shipment booking status

Convert security group

Shipment booking parameters

Document transformations

Shipment booking senders

Shipment booking labels

Shipment booking print favorites

Shipment booking security group (nShift Delivery)

Carrier container types

Shipment booking cost rule

Printers and Printer locations

Import Carrier

Shipment booking app setup

Release highlights Shipment booking

Release notes Shipment Booking

What is Shipment booking

Cepheo Subscription

Setup of subscription

How to use subscription

Release highlights Subscription

Release notes Subscription

Cepheo Test and Certification

Certification and testing

Release highlights Test and certification

Release notes Test and Certification

Cepheo Timesheet

Timesheets

Hour balance

Timesheet extension release highlights

Timesheet extension history

Ts.2022.3.2.15

Ts.2022.3.2.16

Ts.2022.4.2.17

Ts.2022.4.2.18

Ts.2022.4.2.19

Ts.2022.5.2.22

Ts.2022.9.2.24

Ts.2023.2.2.30

Ts.2023.2.2.31

Ts.2023.4.2.33

Ts.2025.3.4.9

Ts.2025.04.4.14

Release notes Timesheet extension

What is Cepheo Timesheet

Cepheo Vendor Catalog

Cepheo Quality and Sample Management

What's new or changed in Quality and Sample Management

Version history

Release notes Cepheo Quality and Sample Management

Version 2025.11.1.9

Version 10.42.66.2

Version 10.42.66.3

Cepheo Quality Sample Management Version 2025.12.1.40

Introduction to Quality and Sample Management

Advanced Quality Control

Setup

Advanced Quality Control

Fail immediately

Update Advance Quality Order Phase based on Quality Order Status

Register test results

Advanced quality work when merging batches (reference type = Inventory)

How to transfer Out of Spec test results to batch attributes

Reservation concept for Batch and warehouse enabled products

View test results

Sample management

Batch disposition master

Disposition code not allowed for location

Preparing disposal of archived samples

Frequencies

Advanced quality associations with ref type different from ‘Quality sample’

Stability testing

Printing of sample labels

Advanced quality associations with reference type ‘Quality sample’

View item tracing

Printing of quality order report

How to transfer test results from bulk batch to Finished Goods batch

Item sampling

Transfer disposition code from Bulk product to finished goods

Manual transfer of test results to batch attributes

Automatic creation of Non-conformance orders

How to enable automatic transfer of test results to batch attributes

Quantities field on Advanced Quality orders

Warehouse management application

Overview - WMS app

Set up a mobile device menu items for receiving processes

Set up a mobile device menu item for changing batch information

Set up a mobile device menu item for registering or adding test results

Set up a mobile device menu item for setting a sample status

Set up a mobile device menu item for changing license plate disposition code

Set up a mobile device menu item for moving sample type

Set up a mobile device menu item for creating a sample

Configure detours for steps in mobile device

Automatic release of license plates

Quality Work Forecasting

Batch Manufacturing Date

Update of manufacturing date

Setup of tracking number group

Update of Expiration Date

Batch Manufacturing Date

Formula Yield Extension

Electronic signature

Quality workspace

Quality workspace

Tab page Advanced quality orders/test results

Tab page Quality samples

Tab page Summary

Data entities

Security

Extension points

Cepheo Global Data Management

Installation

Global data management setup

Validate

Example

Refresh fields setup

Create a data table from a data entity

Recreate company updates

Relation

Table browser

Table setup

InventItemGroupItem

Default values

InventModelGroupItem

Fields setup

Push records

Selection management

Company Distribution

Global data management setup

Record updates

Periodic

Batch push data

Batch push data - multi-threaded

Clean up Event log

Relating existing records

Clean up Record updates

Active is set to Yes

Periodic

Update triggers

Refresh fields setup

GDM monitoring

Overview per company

Managing data

GDM Security setup

Cepheo GDM setup

The company groups setup

Global data management owner

Setting the Cepheo GDM Parameters

Cepheo GDM setup

Known issues

Example: Create new customer

Release highlights Cepheo Global Data Management

Cepheo Global Data Management version 2025.12.1.38

Cepheo Global Data Management version 10.42.66.1

Cepheo Global Data Management version 2025.11.1.7

What is Cepheo Global Data Management

Release notes Cepheo Global Data Management

Cepheo Shipping Packaging Management

License configuration key

License

Terms and abbreviations

Security

Release highlights Cepheo Shipping Packaging Management

Cepheo Shipping Packaging Management version 2025.11.1.3

Cepheo Shipping Packaging Management version 2025.12.1.4

Shipping Packaging framework

Packaging item groups

Packaging management on sales return orders (RMA)

Packaging management automated as part of the sales/purchase order packing slip update

Reporting packaging without order reference

Packaging management on loads/shipments

Packaging management as part of transfer journals

Shipping packaging management setup

Reporting packaging transactions to a pool owner

Settle packaging

Packaging management as part of transfer orders

Packaging management manually on a sales/purchase order

Packaging on-hand

Setup of Packaging Pools

Packaging management for Intercompany and direct delivery

Using mobile device for registration of packaging

Packaging management on a sales/purchase order

Shipping Packaging framework

Advanced packaging management for products

Packaging management for carriers

Packaging groups

Packaging types

Packaging filters and overview

Packaging management for products

Linking registrations to shipment/loads

Packaging management for custoners/vendors

Suggestion production process

Packaging management for transfer orders

Data Management - Entities

Release notes Cepheo Shipping Packaging Management

Feature Management for Cepheo Shipping Packaging Management

What is Cepheo Shipping Packaging Management

Cepheo Product Documentation Management

Security

Document overview groups

Data entities

License configuration key

Product data sheets and batch certificates

Data sheets (PIM\Common\Data sheet)

Basic setup

Printing certificates for a batch

Additional information on data sheets and certificates

Electronic signature – Approve data sheet

Document-specific information

Product data sheets and batch certificates

License

Terms and abbreviations

Release notes Cepheo Product Documentation Management

What is Cepheo Product Documentation Management

Cepheo Product Data Management Extension

Security

BOM Comparison (PIM\Common\Released products)

License configuration key

Terms and abbreviations

Data entities

Customer-specific order settings (PIM\Common\Released products)

Product lifecycles

License

What is Cepheo Product Data Management Extension

Release notes Cepheo Product Data Management Extension

Cepheo Extended Production Handling

License key

Terms and abbreviations

Release highlights Cepheo Extended Production Handling

Cepheo Extended Production Handling version 2025.12.1.4

Cepheo Extended Production Handling version 2025.11.1.3

Data entities

Automatic reporting as finished for sub-productions

Prerequisites and setup

Reporting quantity as finished from finished product

Mix pools

Automatic reporting as finished for sub-productions

Ending productions from finished product production

Concept

Reporting negative quantity as finished from finished product (roll-back)

Reporting overproduced quantity as finished from finished product

Supported process flow

License configuration key

Security

Consolidated batchorders

Consolidated batchorders

Choosing planned bulk orders only

Choosing planned pack and bulk orders

Choosing planned pack orders only

Menus for the planner

Working with the "Firm consolidate batch orders" form

Working with the "Consolidated batch order" form

Quantity view for consolidated batch order

What is Cepheo Extended Production Handling

Release notes Cepheo Extended Production Handling

Cepheo Information Display for Batch Products

License

License configuration key

Entities

Security

Batch Information Display

Batch information display for on-hand

Batch information display groups

Batch information display setup

Batch information display for reservation

Batch Information Display

Batch information display on ‘Batches’ form

Item batch information display group

On-hand list and display dialog

Batch information display for sales order add lines-function

Batch information display for Batch merge

Release notes Cepheo Information Display for Batch Products

What is Cepheo Information Display for Batch Products

Cepheo Advanced Customer Approval

Security

ACA and Intercompany

ACA for trade agreements (Prices)

ACA for sales quotations

Terms and abbreviations

License configuration key

Data entities

Customer exclusion

ACA for sales agreements

Advanced Customer Approval (ACA)

ACA Inquiry forms

Printing sales order

Setup for Advanced Customer Approval

Show only approved products

Using ACA information for purchase

Advanced Customer Approval (ACA)

What is Cepheo Advanced Customer Approval

Release notes Cepheo Advanced Customer Approval

Cepheo Advanced Vendor Management

License

Advanced Vendor Approval (AVA)

Purchase order

Purchase agreement

AVA for trade agreements (Prices)

Advanced Vendor Approval (AVA)

Setup of AVA's on a released product

Source and destination control

License configuration key

Security

Vendor exclusion

Data entities

Vendor Audit Management

Audit records

Vendor Audit Management

Number sequence for Vendor Audit

Vendor audit score

Vendor audit status

Audit requirement

Vendor and manufacturer certifications

Terms and abbreviations

Release notes Cepheo Advanced Vendor Management

What is Cepheo Advanced Vendor Management

Release notes AVM

Cepheo Label Extension for Warehouse Management

Label viewer tool

Warehouse document routing layout

Security

Terms and abbreviations

License

Entity

Configuration keys

What is Cepheo Label Extension for Warehouse Management

Release notes Cepheo Label Extension for Warehouse Management

Release notes LEWM

AX2012

Cepheo MVA-melding

MVA Setup

MVA Reporting

Step 4: Reporting

Step 4 | Section 1: Tax reports

Step 4 | Section 2: Standard tax codes

Step 4 | Section 3: Tax specifications

Step 4 | Section 4: Report remark

MVA Multicompany setup

MVA Intercompany setup

MVA Intercompany Tax report

Cepheo SAF-T reporting

- All Categories

- Cepheo Quality and Sample Management

- Advanced Quality Control

- How to transfer test results from bulk batch to Finished Goods batch

How to transfer test results from bulk batch to Finished Goods batch

Updated

by Peter Kure Bek-Thorngreen

Test results from bulk batch to Finished Goods batch.

Purpose

The primary goal of this manual is to streamline the transfer of quality test results from bulk products to finished goods, ensuring that production processes are efficient, traceable, and adhere to quality standards. By leveraging Bill of Materials (BOM) and Formula methodologies, along with batch attributes, this manual provides a detailed framework for maintaining consistency and accuracy in test result transfers, regardless of the presence of direct quality work on finished goods.

Overview

Finished goods production is a complex process that involves the consumption of one or more bulk products. Each production cycle may include various item numbers and batch numbers, but all are derived from the same bulk productions. The ability to accurately transfer test results from bulk product batches to finished goods batches is crucial for maintaining product integrity and ensuring compliance with quality standards.

In this manual, we will explain each setup item and then explore different scenarios where the outlined functionality should be possible. Each scenario is designed to address specific challenges and provide solutions for transferring test results under various conditions, such as differing bulk product batches, open advanced quality orders across production, and advanced setups involving multiple bulk productions.

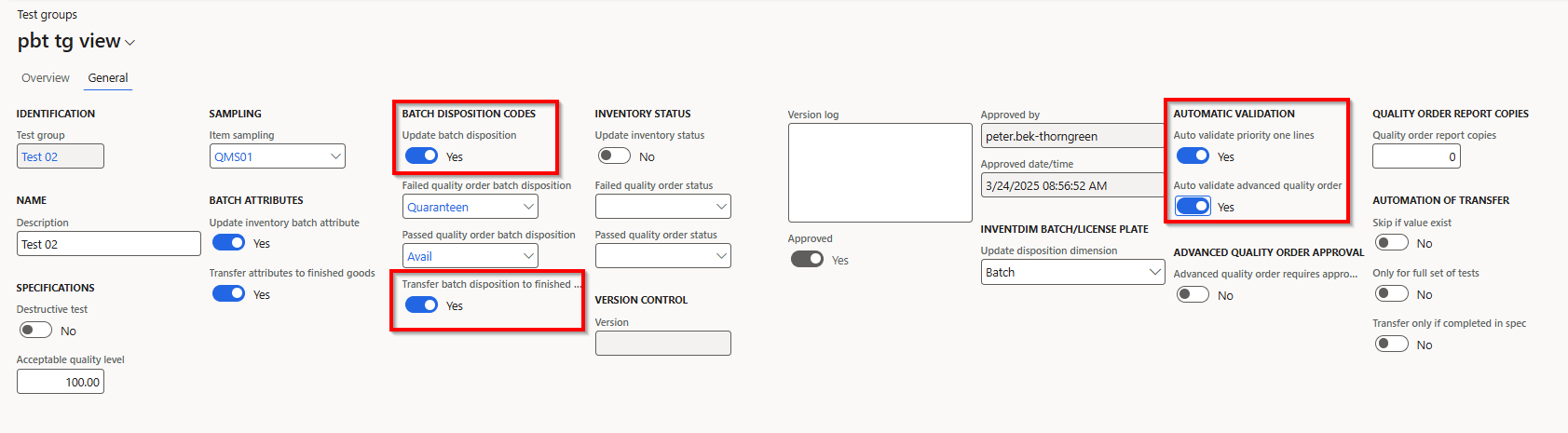

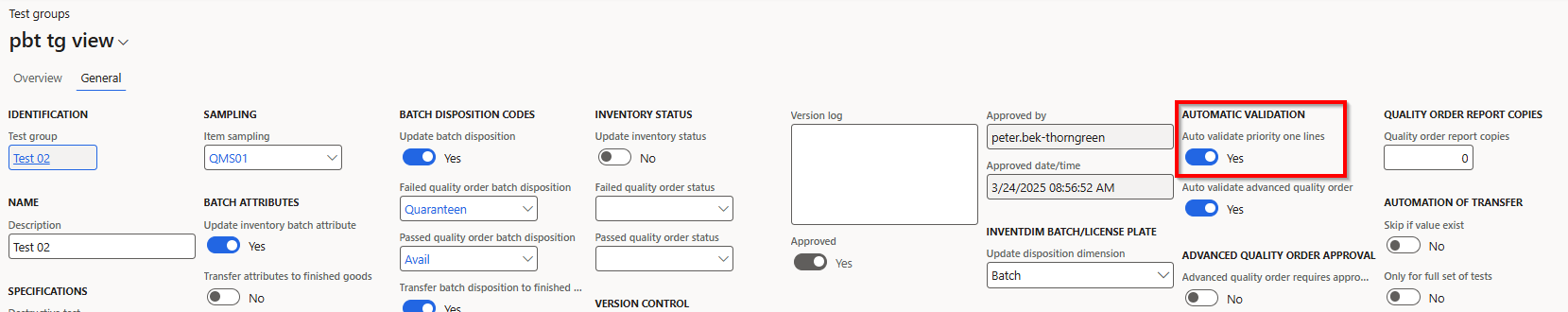

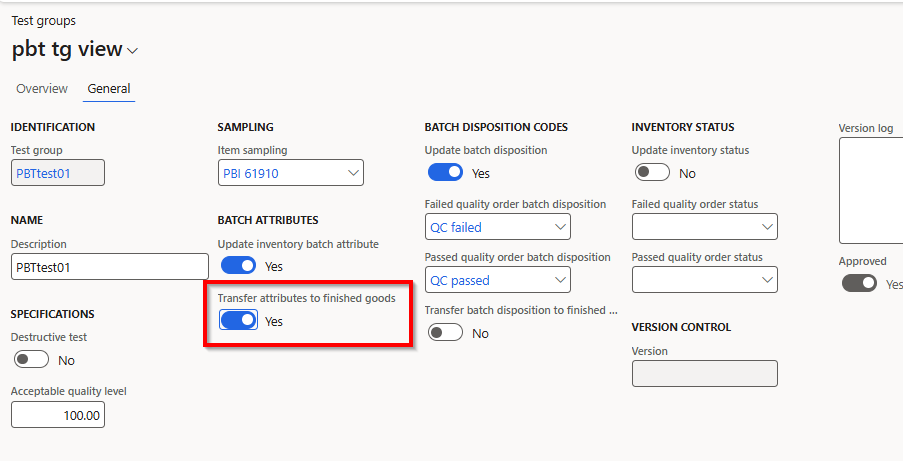

The code is triggered by the Report as Finished operation on the production order and by the following settings on the Test Group, which is copied to the Advanced quality order.

The "Update batch disposition" and the two settings under Automatic Validation have been a part of the module a long time, and their functionalities are described elsewhere.

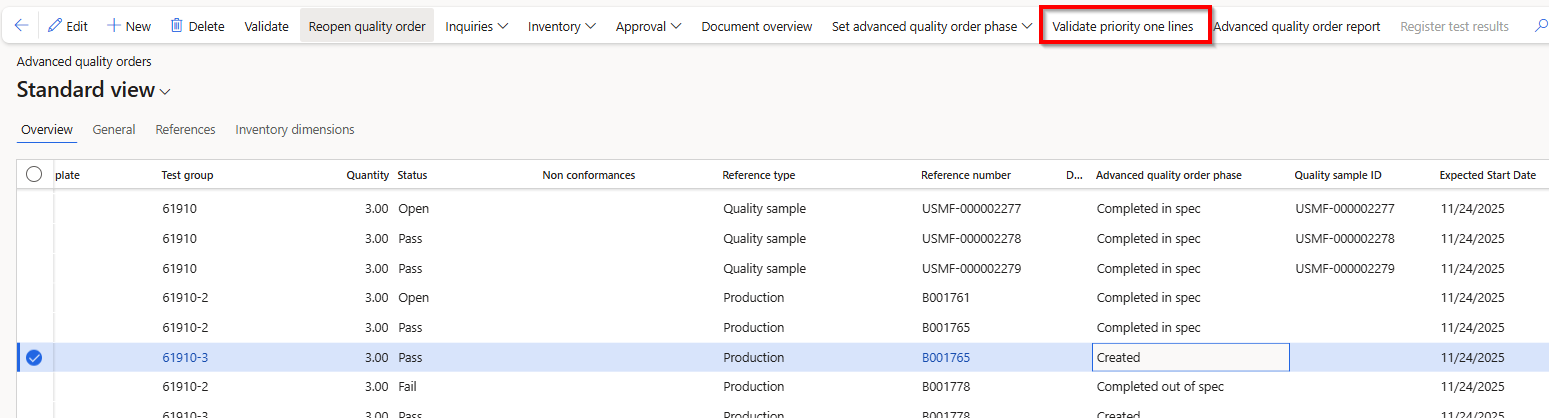

It is possible to validate both priority 1 tests and the Advanced quality order manually by pressing validate buttons. This is also covered in other articles.

The new button on Test Group / Advanced quality order "Transfer batch disposition to finished goods" is the new parameter which ensures that the code is run for transferring disposition code to finished goods.

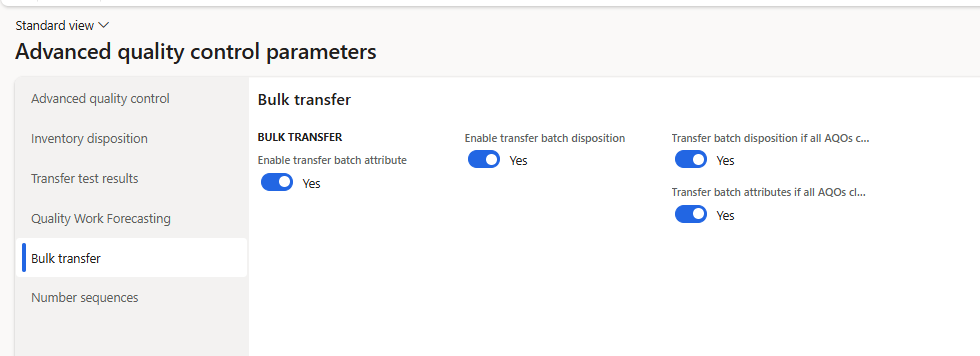

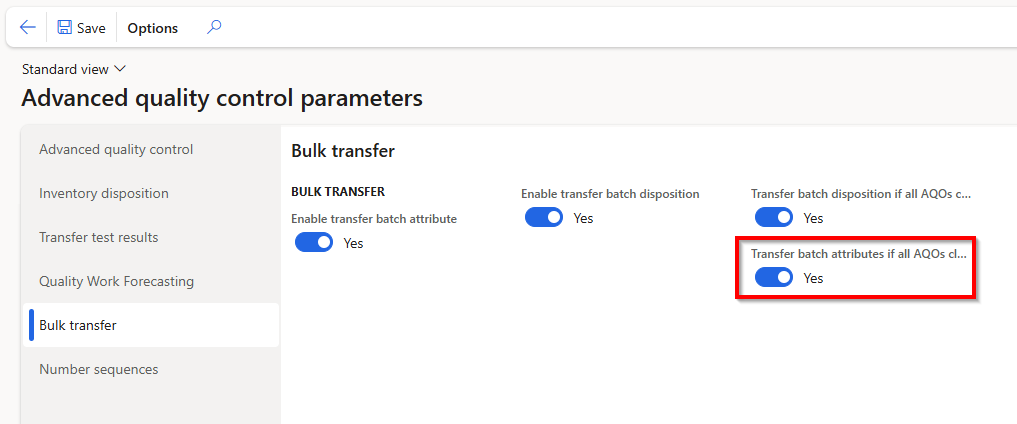

Open orders - settings in Advanced quality control paramters

TITLE | FUNCTION |

Enable transfer batch attribute | Enables the functionality which can transfer batch attributes from bulk productions to finished goods production including the min/max/first/last option. |

Enable transfer batch disposition | Enables the functionality which can transfer disposition code from batches to the finished goods batch and/or license plates. |

Transfer batch disposition if all AQOs closed | Affects the time when batch disposition can be transferred. If toggled to yes all connected advanced quality orders must have status pass/fail before the transfer will take place. |

Transfer batch attributes if all AQOs closed | Affects the time when batch attributes can be transferred. If toggled to yes all connected advanced quality orders must have status pass/fail before the transfer will take place. |

First of all, the settings in the new menu under Advanced quality control parameters - Bulk transfer - needs to be correct.

An important setting to take into account is the "Transfer batch attributes if all AQO's closed" found under advanced quality control parameters.

This setting will by default be toggled to "no".

(The meaning of "connected advanced quality orders" below is all advanced quality order in connection with a production batch.)

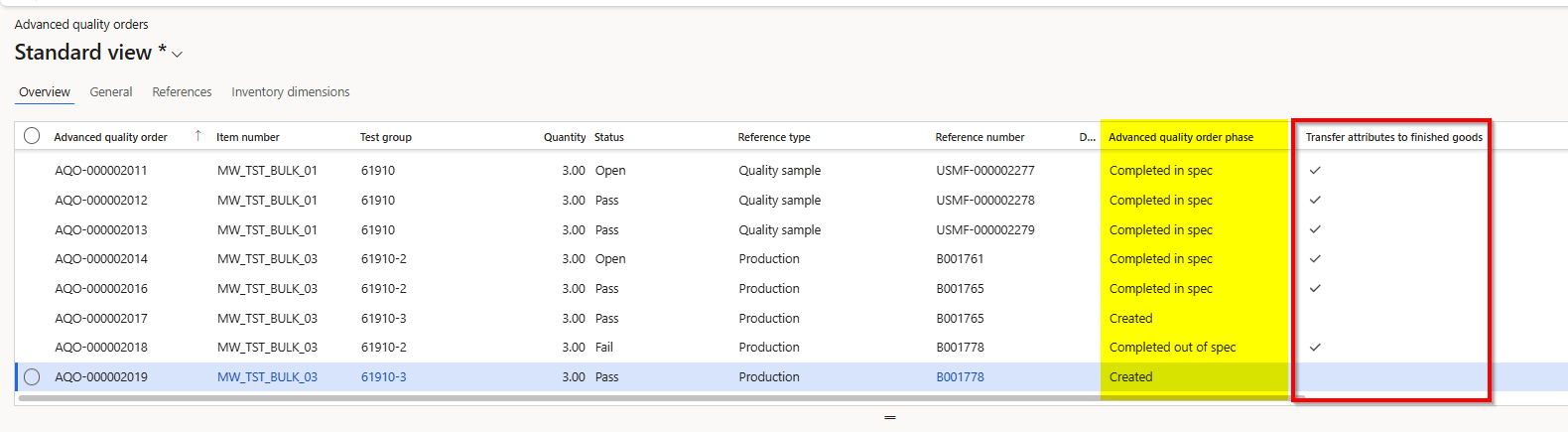

The system will not trigger the code, if there are open Advanced quality orders, which means that all connected advanced quality orders have to be completed.

Toggled to no, the code will be triggered, when all connected Advanced quality orders change Advanced quality order phase to completed in spec / completed out of spec.

This can be a problem if there are connected Advanced quality orders with no priority 1 tests, since the phase will never change to completed in spec / completed out of spec and thus be interpreted as an order still open.

Example 1:

Two AQO's are created on the bulk batch. One with priority 1 and 2 tests and one with only priority 1 tests.

If the parameter is set to no, the code will be triggered based on the priority 1 tests on both AQO's. The priority 2 tests will have no effect.

If the parameter is set to yes, the code will not be triggered before the priority 2 tests have been completed and the AQO status is set to pass/fail.

Example 2:

Two AQO's are created on the bulk batch. One with priority 1 and 2 tests and one with only priority 2 tests.

If the parameter is set to no, the code which should be triggered based on the priority 1 tests will not be triggered, because the AQO with priority 2 tests will have the Advanced quality order phase as "created" and be treated as an "open" order.

The priority 2 tests will have no effect.

Only if the AQO with the priority 2 test has the Advanced quality order phase changed manually to completed in spec / out of spec before the AQO with priority 1 tests is completed, the code will be triggered.

If the parameter is set to yes, the code will not be triggered before the priority 2 tests have been completed and the AQO status is set to pass/fail.

Setup for test results from bulk batch to Finished Goods batch.

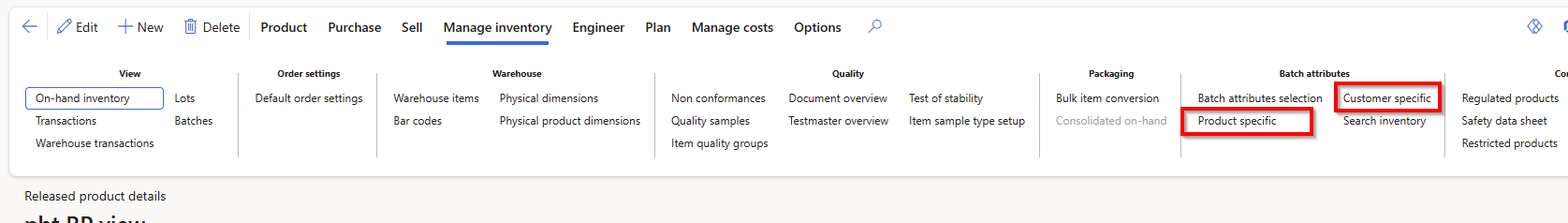

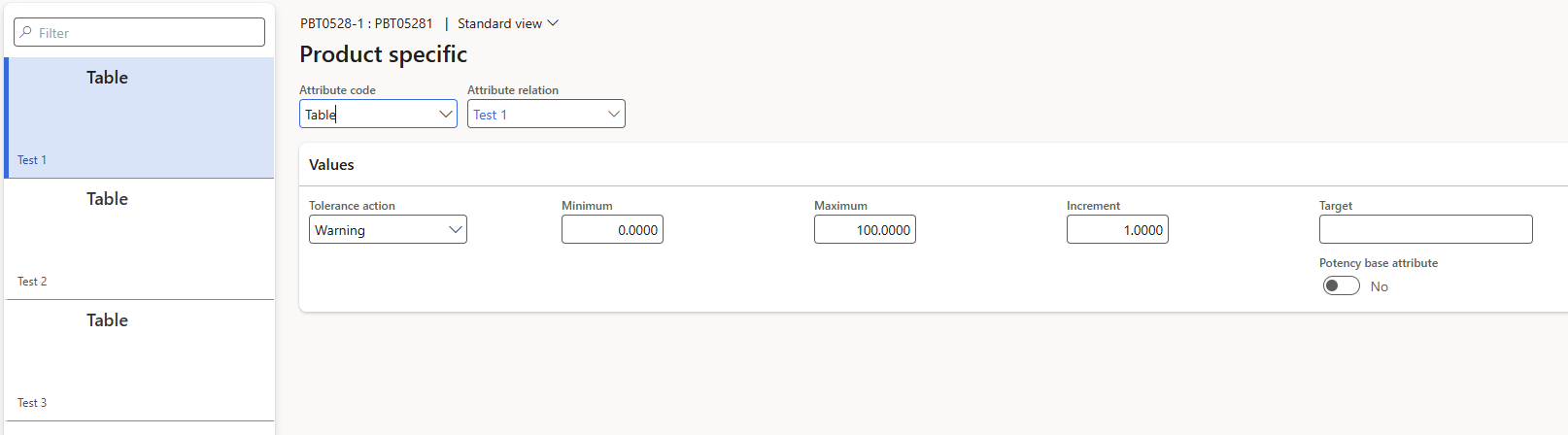

The base for the functionality is the attribute setup on the released products. The same attributes must be setup on both bulk and finished goods product.

Common for both bulk and finished goods products is that the attributes must be active under product specific and customer specific found under "manage inventory" in the batch attributes section.

As explained in Microsoft Learn the product specific setup lets you choose the different product specific attributes and then connect attributes and set tolerances for customers.

Without this setup, no attributes will be transferred.

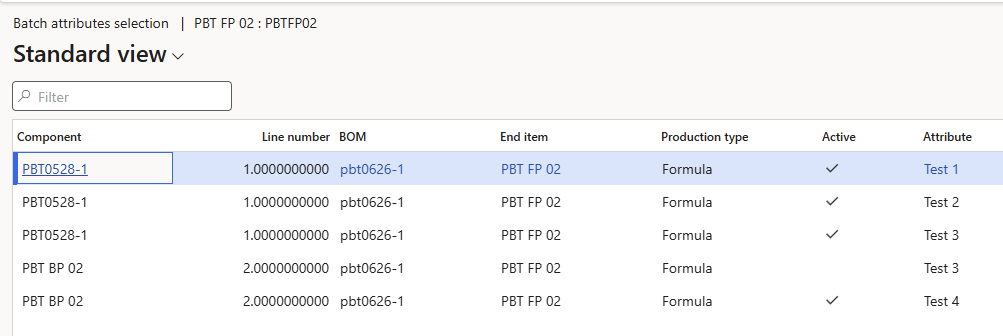

Batch attribute selection

For the finished goods there is a BOM / formula defining, which products are used to create this finished goods product.

Under batch attribute selection on the finished goods product, a choice of which attributes should be transferred as well as from which bulk products must be made.

In the example below there are two different bulk product going into one finished goods product. Test 1 and 2 are unique for bulk product PBT0528-1.

Test 4 is unique to bulk product PBT BP 02, but test 3 is present on both bulk products.

In this case a choice must be made as to which bulk product should provide test results to the finished goods product. In the screenshot below it is to use the results on test 3 for PBT0528-1.

Bom / Formula

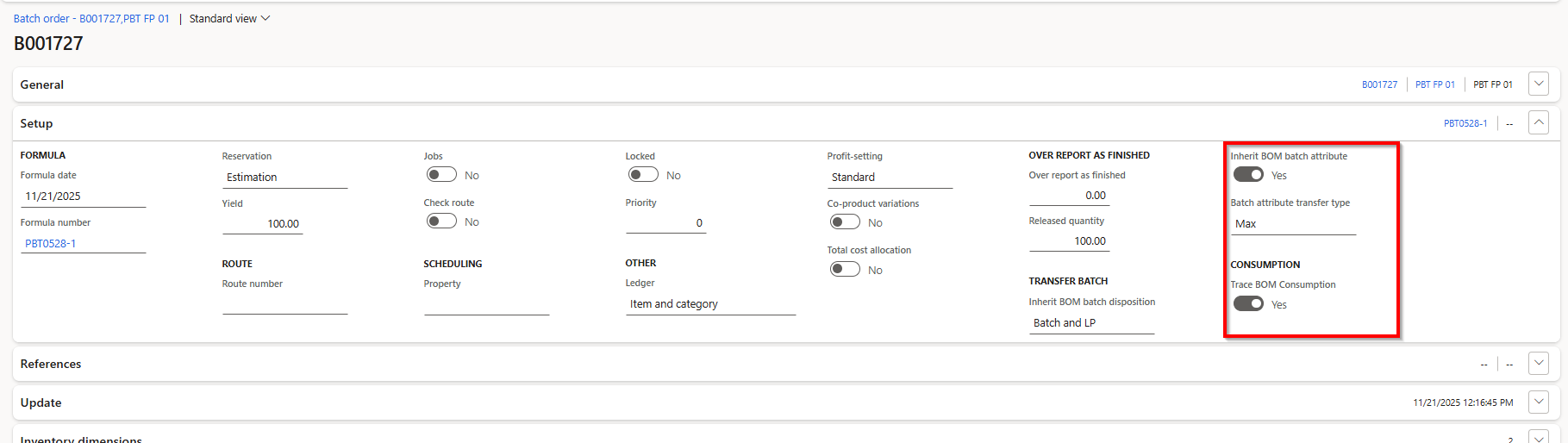

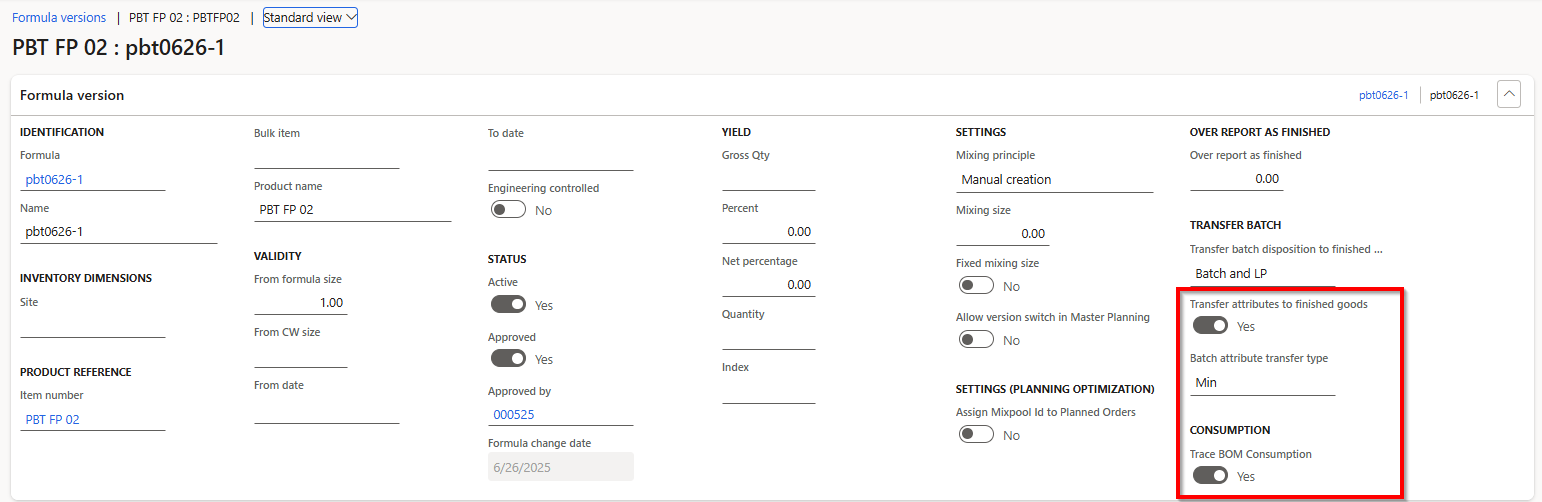

The settings below are transferred to the production order under setup

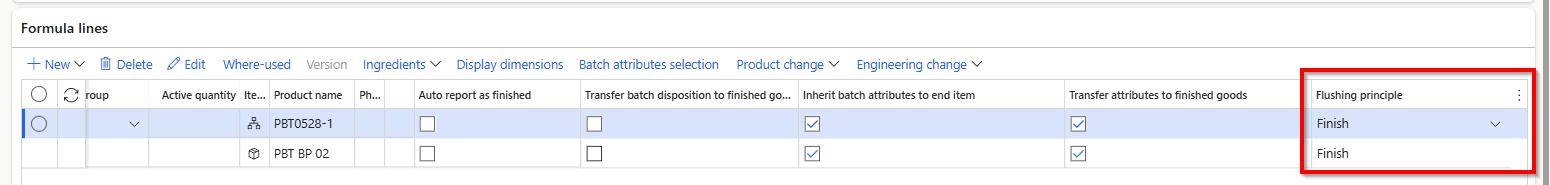

And under the formula lines

Header:

On the formula header a couple of settings are needed.

The logic below ensures that test results on the bulk batch attributes are transferred to the finished goods batch attributes at the time of Report as Finished.

It does not transfer at the time the advanced quality order is completed, unless the setting on the test group / advanced quality order is correct. See section below.

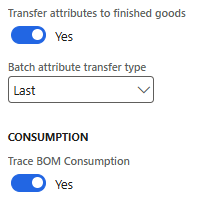

On the formula header the “transfer attributes to finished goods” must be toggled to yes to trigger the automatic transfer of attributes in all scenarios described later.

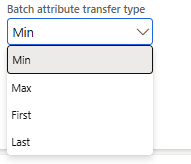

The “Batch attribute transfer type” can be set to four different settings.

Min:

The lowest value will be transferred to the finished goods batch attribute. The functionality will evaluate each result towards the existing and overwrite if a new value is lower than the value already on the batch attribute.

Max:

The highest value will be transferred to the finished goods batch attribute. The functionality will evaluate each result towards the existing and overwrite if a new value is higher than the value already on the batch attribute.

First:

The first value transferred will be added to the batch attributes. Any subsequent values will be ignored.

Last:

The values will be overwritten whenever a new value is transferred in batch attributes

Under Consumption the “Trace BOM Consumption” must be toggled to “yes” to allow for the register of consumption to be active. The system needs to have the information as to which bulk batches has been consumed into the finished goods.

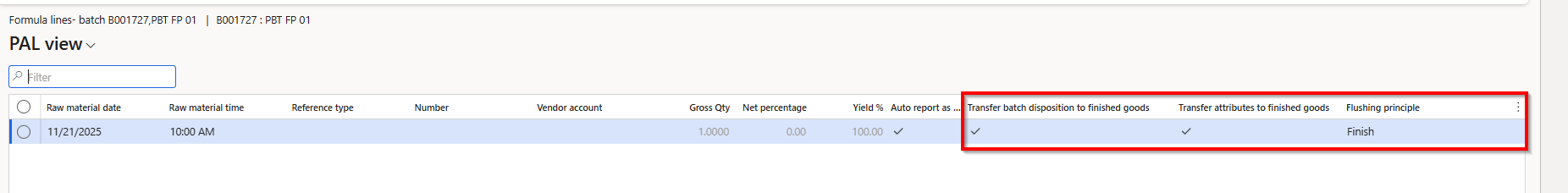

Formula line:

Two settings on the formula line has to be checked.

The inherit batch attributes to end item has been a setting in the system for a long time ensuring that the transfer will happen at the Report as Finished.

Transfer attributes to finished goods is the added functionality where the calculation of min/max/first/last is added as well as the possibility to transfer when an advanced quality order on the bulk product has the transfer possibility enabled as well.

Prerequisite for flushing principle

IMPORTANT: For the picking list and consumption to follow the correct procedure and link the consumption to the correct bulk batches, the flushing principle must be set to “finish”.

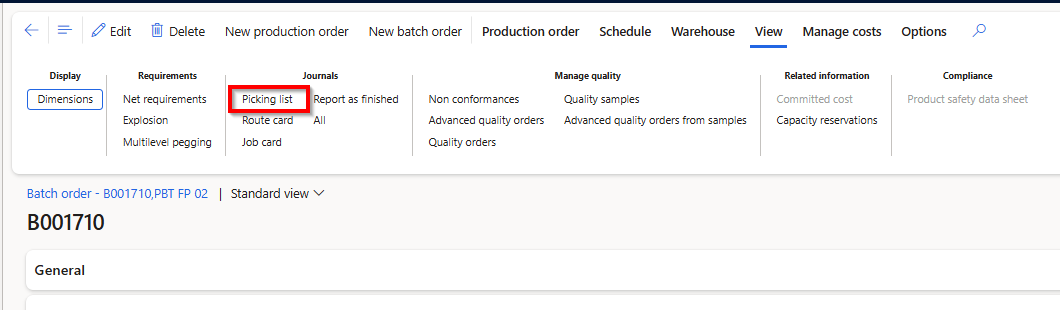

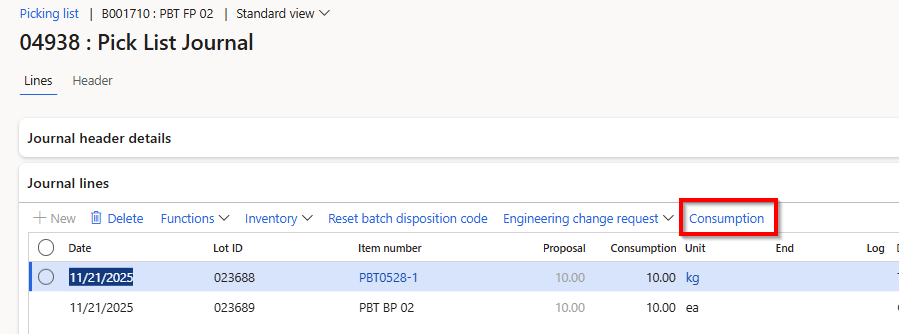

Consumption/picking list

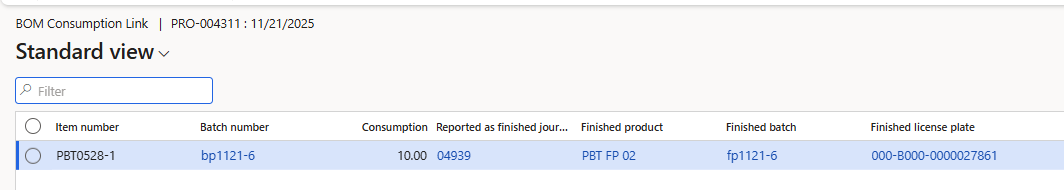

When the production runs, the picking list journal will include a new consumption table.

The BOM Consumption link contains information about which batch it originates from and what finished goods it has become – including the license plate.

Settings on the test group

On test group it is possible to set “transfer attributes to finished goods” to yes.

By doing so the transfer, which is happening at the time of Report as Finished, will also happen when the advanced quality order phase change to completed in spec / Completed out of spec.

The setting on the test group is inherited to the advanced quality order, where it is also possible to change it:

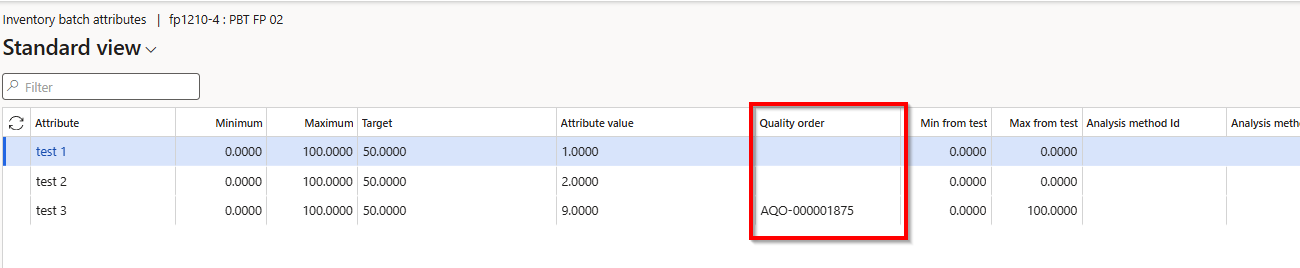

Results on finished goods batch

When looking at the transferred results on the finished goods batch, the situation could look like below where there are only reference to Advanced quality orders on some of the result.

The reason is related to WHEN the results are transferred.

If they are transferred at the point of Report as Finished, the system refers to the existing results on the bulk batch, but the system does not know how the results have been applied to the bulk batch attributes. It could be an Advanced quality order or it could have been results entered or corrected manually. This is why there is no reference.

On the other hand when the transfer from bulk batch to finished goods batch is triggered by an Advanced quality order, the system knows which order is the reference and that reference can be added to the attribute line on the finished goods.

Scenarios

Scenario 1:

Transfer of test results from completed bulk product AQO to finished goods batch attributes.

User Story: As a production manager, I want the test results from the completed Advanced Quality Order on bulk product A0001 to transfer to Finished Goods batch number 0408-06, when FG item 21015103 is produced. The batch attributes on the finished goods should include the last result.

Settings:

- On the bulk product A0001 the product specific and customer specific attributes are setup.

- On the finished goods item 21015103 the similar attributes are setup.

- On the batch attributes selection, the correct attributes from A0001 are set to active.

- On the formula header the settings are these:

- On the formula lines only the line for bulk product A0001 should have a checkmark in “transfer attributes to finished goods”.

Scenario 2:

All advanced quality work is not done, when the finished goods are produced, but the transfer of test results needs to happen as soon as the advanced quality orders are done.

This must happen towards multiple finished goods productions, which have all consumed from this bulk product.

Settings:

Same settings as above, but with this addition:

- On the test group header for the test group used in connection with the bulk production, the “Transfer attributes to finished goods” must be toggled to yes.

- The other settings about transfer of batch attributes described in another article here will also affect which results are transferred.

The “Trace BOM Consumption” and the flushing principle set to “finish” ensures that the consumption is linked from bulk to finished goods productions.